Dec 04,2024

The transformer will generate heat during operation, and at this time, the cooling system is needed to reduce the heat of the transformer and avoid the adverse effect of overheating on the transformer.

Identification of oil-immersed transformer cooling system

In the IEEE standard, the common cooling methods of oil-immersed transformers are: ONAN,ONAF,KNAN and KNAF.

The cooling system of the transformer is identified by four letters, the first two letters are the cooling system of the iron core and coil inside the transformer, and the last two letters are the external cooling system of the transformer.

The iron core and coil in the internal winding release heat in the internal box, and the oil acts as the internal cooling medium to assist in heat dissipation. “O” stands for general mineral oil or synthetic fluid, QXG uses mineral oil as the internal medium of the transformer, in some places with high requirements for transformer safety and environmental performance, vegetable oil will be used, and the corresponding transformer price cost will increase.

The second letter "N" we see stands for natural convection. The internal circulation mechanism can be divided into natural convection and forced circulation.

Natural convection is suitable for some small oil-immersed transformers, where heat is transferred through the iron core and coil, directing the winding heat inside the transformer to where the heat is less.

The forced circulation system is suitable for large volume oil-immersed transformers. Because natural convection can not meet the heat transfer inside the transformer, can not reduce the internal heat, it is necessary to force circulation to reduce the transformer heat. The insulating oil in the mailbox will flow through the cooling device to the internal system, forcing cooling.

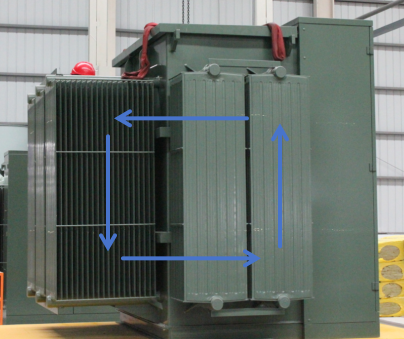

A radiator auxiliary transformer is installed outside the transformer for heat dissipation. When the very hot insulating oil is cooled by the external system, it will pass through the transformer housing and heat sink and contact with the external air to achieve the cooling effect. The third letter, common "A", indicates that the insulating oil circulates through the natural air outside the housing.

Because substation transformers are generally used in some places with very high power requirements, the heat inside the transformer will be very high, and natural convection or forced circulation may be used to enhance the cooling effect. The fourth letter N is cooled by natural convection, and F is cooled by forced circulation through the cooling surface to achieve the effect of insulating oil cooling.

Below is a diagram of the cooling method:

Cooling method of dry transformer

IEEE standard dry transformer cooling methods include AA and AF.

Dry transformers rely on air circulation for cooling, through the transformer external ventilation system for cooling, through the replacement of internal air and external air, to achieve the transformer internal cooling. Some dry transformers do not have external ventilation equipment, you need heat sink to achieve cooling effect.

QXG transformers are exported to the United States, Canada and other countries. The QXG team is excellent in transformer design and expertise and brings the best solution for each project. If you are looking for a reliable transformer supplier, please contact us now!

QXG Technology provides you with a one-stop solution for transformers!