Tørrtransformatorer av amorfe legering er forskjellige typer transformatorer som er laget av forskjellige materialer. De er ikke ordnet i noen rekkefølge, så de små tingene inni dem - atomer og molekyler - blir blandet sammen tilfeldig. En slik tilfeldig konfigurasjon er det som definerer disse transformatorene som "amorfe. Den pålitelige transformatoren inneholder lag av jern og silisium så tynne som et enkelt menneskehår.

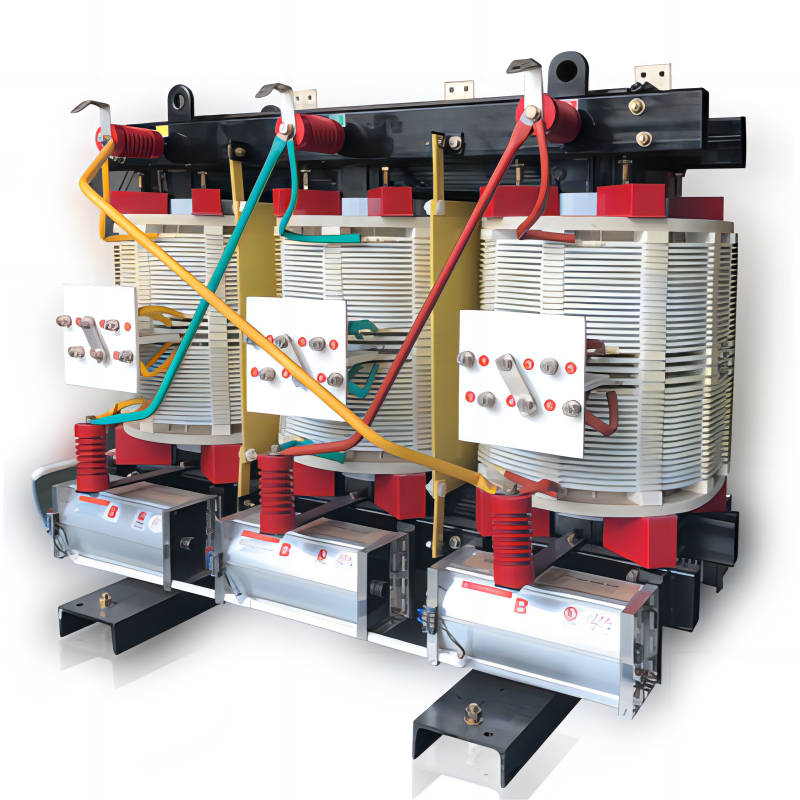

Disse tynne lagene, som så ut som bånd, ble forsiktig viklet rundt en sentral komponent kalt den magnetiske kjernen. Vikleprosessen er kritisk for hvordan elektrisitet flyter gjennom transformatoren. Tørrtransformatorene, i stedet for olje eller gass som isolasjon og kjølemedium som de i tradisjonelle transformatorer, bruker materialer som ikke er brennbare. Denne designen gjør at de kan være betydelig tryggere, siden det ikke er mulighet for farlig søl eller lekkasje noe sted.

Sammenlignet med den tradisjonelle oljefylte transformatoren, har de amorfe legeringstransformatorene mange fordeler som lar dem skinne og være unike. Til å begynne med er en av deres største styrker energisparing. De er mer effektive, noe som betyr at de bruker mindre strøm. Atomene og molekylene er organisert på en bestemt måte som gjør det vanskeligere for elektrisiteten å bevege seg under normale forhold, men de har ikke så god organisering som betyr at elektronene deres kan flyte lettere.

Som følge av denne økte elektriske flyten, bruker disse transformatorene mindre energi for å konvertere høyspentkraften til en mye lavere og brukbar strømspenning som vi trenger for våre hjem så vel som bedrifter. For det andre: De er like stille når de fungerer som transformatorer. Siden de er stille som faen og ikke produserer noen vibrasjoner, kan du bruke disse hvor som helst uten å bry deg.

Nummer tre, disse transformatorene er også utrolig robuste og langvarige. Disse systemene kan vare i flere år uten behov for utskifting eller vedlikehold, noe som gjør dem perfekte for de som bruker disse. Til slutt er sikkerheten til disse transformatorene en stor pro. De har ikke olje, så det er ingen risiko for søl eller lekkasje, derfor reduseres også sjansen for miljøforurensning sammen med brannfare.

Dette er transformatorer du kan finne på en rekke steder fra små boliger til store industrifabrikker. Tallene går i byggemarkeder, haller, kommersielle arbeidslokaler som butikker osv. En grunn til at de ofte blir samplet er deres allsidighet, noe som gjør at de passer godt for mange forskjellige bruksområder og steder i samme oppsett.

Oljefylte transformatorer har eksistert lenge, og de har gjort tiden sin, men til syvende og sist er det bare vondt. Søl, lekkasjer eller eksplosjoner kan potensielt forårsake skade på miljøet og mennesker på grunn av deres høyere risiko. Dessuten er disse svært tungvinte og kan fungere ganske ineffektivt ved full belastning, de utgjør en miljøfare siden bruk av impregnert olje.

Du kan forvente en full råvarekjede, kvaliteten kan kontrolleres i hvert trinn. Amorf legering tørr-type transformator QC kan nås online, sammen med forhåndslasting og råmateriale. Vi har evnen til å sørge for at de fleste varer er av utmerket kvalitet. Hvert av våre produkter kan tilpasses for å møte standardene du ønsker og består av IEC, IEEE, CSA, UL, GOST, TIER.

Vi er en ledende produsent av våre QXG og produktene inkluderer 110KV 220KV store ultraspenningshøye og 35KV under tørre transformatorer, oljenedsenkede transformatorer, amorfe legeringstransformatorer, forhåndsinstallert en transformatorstasjon i tillegg til en rekke spesifikasjoner for pakketransformatorer, ovnstransformatorer likerettertransformatorer , gruvetransformatorer og andre spesielle transformatorer.

Fabrikken inkluderer en stor produksjon og svært amorf legering tørr-type transformator. Betydelig mer enn 20000 4 transformatorer er tilgjengelige på vårt senter hvert år. Vår tid til å produsere vanlige transformatorer mellom 6-6 uker. For tilpassede løsninger er det egentlig 8-XNUMX uker.

QXG er et ekspertselskap innen elektrisk kraft i mer enn to tiår. Fabrikken er virkelig en viltvoksende bygning på 240,000 1000 kvadratmeter med mye mer enn 200 ansatte, inkludert XNUMX teknikere pluss designere.