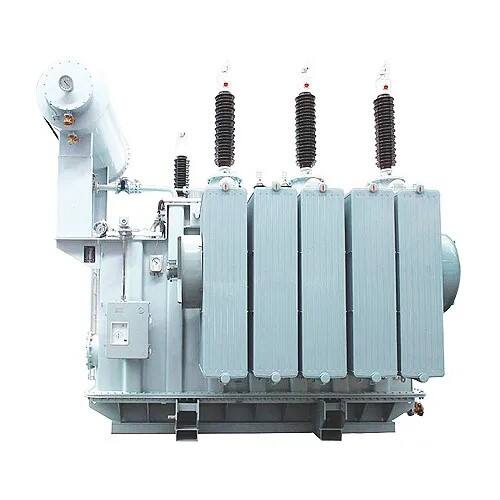

Olie-ondergedompelde kragtransformator 'n Olie-ondergedompelde kragtransformator, is 'n baie spesiale soort masjien wat dit moontlik maak om elektrisiteit van een plek na 'n ander op veilige manier te verskuif. Dit is 'n groot metaalboks wat vol belangrike onderdele soos drade en ander dinge dit laat werk, kan jy dit sê, uit as die hart van jou motor. Die kans is groot dat jy jou brein opgeskerp het met swastiktransformers by plekke van die huis, skool, kantore of selfs fabrieke. Krag vir ons daaglikse lewens, hulle is krities op een of ander manier.

Spole - Daar is twee spoele in die transformator. Eerste deel is primêre wikkeling. Dit is waar elektrisiteit inkom; Die ander aspek staan bekend as die sekondêre spoel waar dit vonke. Koperdraad, bekend vir sy uitstekende geleidingsvermoë van elektrisiteit, word gebruik om hierdie spoele te vervaardig. Hierdie spoele draai om 'n ysterkern. Die ysterkern help om die vloei van elektrisiteit reguit te maak om algehele transformatordoeltreffendheid te verbeter.

Olie word binne-in die transformator bygevoeg om dit moontlik te maak dat elektriese energie rondbeweeg. Hierdie olie is op 'n baie sinvolle manier gebruik. Dit gelei elektrisiteit maar het ook die voordeel van 'n koeler masjien. Verkoeling is noodsaaklik aangesien 'n transformator wat te warm word óf heeltemal kan ophou werk óf selfs uitbrand. Dit smeer die ratte sodat dinge op 'n vloeibare, relatief wrywingvrye en veilige manier werk.

Daar is baie voordele daaraan verbonde om transformators met olie ondergedompelde te hê. Hulle is hoogs doeltreffend om elektrisiteit van een punt na 'n ander te vervoer. Dit is waardevol omdat dit die vermorsing van energie tot die minimum beperk. Hierdie transformators kan ook baie krag dra. Dit is veral krities in gebiede met so 'n groot kragbehoefte (bv. fabrieke of groot geboue).

Olie-ondergedompelde transformator: Ten spyte van die verskillende gebruike van olie-ondergedompelde transformators, het hulle ook hul nadele. Hulle kan egter 'n bietjie lywig en swaar wees. Dit kan byvoorbeeld 'n probleem wees op plekke waar dit nodig is om alarms te installeer, maar daar is nie genoeg spasie daarvoor nie. Een nadeel is dat dit duur en vervelig kan wees om te skep en in stand te hou. Jy moet ook verseker dat hulle in die regte vorm bly, 'n taak wat hul algehele koste kan verhoog.

Tipe olie. Daar is verskillende kwaliteite in olie wat in wese 'n direkte impak op die algehele funksionaliteit van die transformator kan hê. Minerale olie word byvoorbeeld gereeld gebruik aangesien dit 'n hoë diëlektriese waarde het, maar sekere transformators kan beter werk met ander vorme van olie soos silikoonolies.

Oorverhitting. As die transformator te warm is, hetsy as gevolg van 'n lae hoeveelheid olie in sy tenk of as gevolg van hoë atmosferiese temperatuur. Gereelde kontrole van olievlakke, tesame met 'n strategiese ligging weg van enigiets wat die stelsel tot oorverhitting kan beklemtoon, soos ander masjinerie of hittebronne, is sleutelpunte.

Ons is die QXG-betroubare vervaardiger. Ons bied 'n aantal produkte|wye reeks}, soos 110KV- en ultrahoë-220KV-spanning en 35KV-transformators onder die droëvlak, ook as oliegedompelde plus amorfe-legeringstransformators.

QXG is 'n verskaffer wat plaasvind om kundige te wees in die elektriese krag vir meer as twee dekades. Die fasiliteit is 'n fasiliteit van 240,000 1,000 vierkante meter met meer as 200 XNUMX werknemers, insluitend XNUMX ingenieurs en tegnici.

Ons verskaf 'n volledige grondstofketting wat toelaat dat kwaliteit deur elke proses beheer word. Olie-ondergedompelde Power Transformer QC is aanlyn beskikbaar, tesame met die vermoë om plus QC van natuurlike materiale vooraf te laai. Ons kan verseker dat alle goedere van hoë gehalte is. Elkeen van ons produkte kan aangepas word om te voldoen aan die standaarde wat jy regtig wil hê jy moet IEC, IEEE, CSA, UL, GOST, TIER insluit.

Ons fabriek is toegerus met die vervaardigende Olie-gedompelde Kragtransformator wat die nuutste was. Aansienlik meer as 20,000 4 transformators word elke jaar in ons fabriek aangegee. Vir gewone transformators neem ons vervaardiging ongeveer 6 weke. Vir pasgemaakte oplossings is ons produksietyd tussen 8 plus XNUMX maande.